Electronics

Chip On Board Epoxy (COB) Chip On Board Epoxy (COB)The chip-on-board epoxy has excellent thermo-mechanical properties and adhesion strength that provides maximum protection to the components, ICs and bonded wires. Dam and fill epoxy are suitable for encapsulation of bigger components and ICs. Application: PCBA (Printed Circuit Board Assembly), sealing and bonding of electronic components and devices. |

||||||

|

Product Code

|

Special Features

|

Appearance

|

Cure (˚C/ Time)

|

Mixed Viscosity

(cP at 25°C) |

Shelf Life

(month) |

Tg (˚C)

|

|

White paste | 2hrs @ 125°C | 32,000 | 6 | 125 | |

|

White paste

|

1hr @ 120°C or 30 mins @ 150°C |

220,000

|

12

|

125

|

|

|

Black paste

|

2hrs @ 120°C or

1hr @ 150°C |

52,050

|

6

|

140

|

|

|

Black paste | 1hr @ 120°C or 30mins @ 150°C |

30,820 | 12 | 152 | |

|

Black paste

|

1hr @ 100°C or 30mins @ 120°C |

30,000

|

9

|

112

|

|

|

Black paste

|

1hr @ 100°C

|

23,850

|

6

|

111

|

|

|

|

|

Black viscous liquid

|

30mins @ 150°C

|

4,800

|

6

|

NA

|

|

Clear +

clear yellow liquid |

2hrs @ 25°C

|

1,700

|

12

|

80

|

|

|

Black | 2hrs @ 85°C or 1hr @ 100°C | 23,460 | 6 | NA | |

|

Black | 2hrs @ 100°C | 9,850 | 6 | NA | |

|

White | 2hrs @ 125°C or 1hr @ 150°C | 140,000 | 6 | 125 | |

|

Black | 2hrs @ 110°C or 1hr @ 120°C | 1,800 | 12 | 100 | |

|

Slight Translucent | 2hrs @ 100°C | 4,300 | 6 |

-98 |

|

|

Slight Translucent | 2hrs @ 100°C | 3,424 | 6 | -108 | |

|

Black | 30mins @ 150°C or 2hrs @ 100°C | 7,956 | 6 |

-102

|

|

|

Black | 30mins @ 150°C | 1,734 | 6 | NA | |

|

Clear to sligh yellowish | 2hrs @ 25°C | 1,700 | 12 | NA | |

SMT Epoxy / Die Attach SMT Epoxy / Die AttachThe SMT epoxy is designed for high speed dispensing with good green strength to hold components in the bond pads. The viscosity and thixotropy are optimized with no bleeding and tailing. Application:

PCBA (Printed Circuit Board Assembly), sealing and bonding of electronic components and devices. |

||||||

|

Product Code

|

Special Features

|

Appearance

|

Cure (˚C/ Time)

|

Viscosity (cP)

|

Shelf Life

(month) |

Tg (˚C)

|

|

Red paste | 90s @ 150°C or 300s @ 115°C |

30,000 * | 12 | 120 | |

|

Black paste | 5mins @ 150°C, 20mins @120°C or 30mins @ 100°C |

5,500,000 ** | 6 | 131 | |

|

Red paste | 90s @ 150°C or 2hrs @ 80°C |

5,000,000 ** | 12 |

135 |

|

|

Red paste | 5mins @ 150°C, 20mins @ 120°C or 30mins @ 100°C |

6,000,000 ** | 12 |

124

|

|

|

Black paste | 40mins @ 80°C | 42,250 | 6 | 120 | |

|

Red paste | 90sec @ 150°C or 5min @ 120°C or 15min @ 100°C | 17,000 | 6 | NA | |

|

Red paste | 5min @ 150°C or 2hr @ 80°C |

118,533* 4,000,000** |

12 | 101 | |

|

Red | 90s @150°C or 5min @ 150°C | 223,300*** | 12 | 101 | |

| * Vicosity tested at CAP 2000+ viscometer, 25°C, Cap-06@100rpm ** Vicosity tested at Brookfield RVT, 25°C |

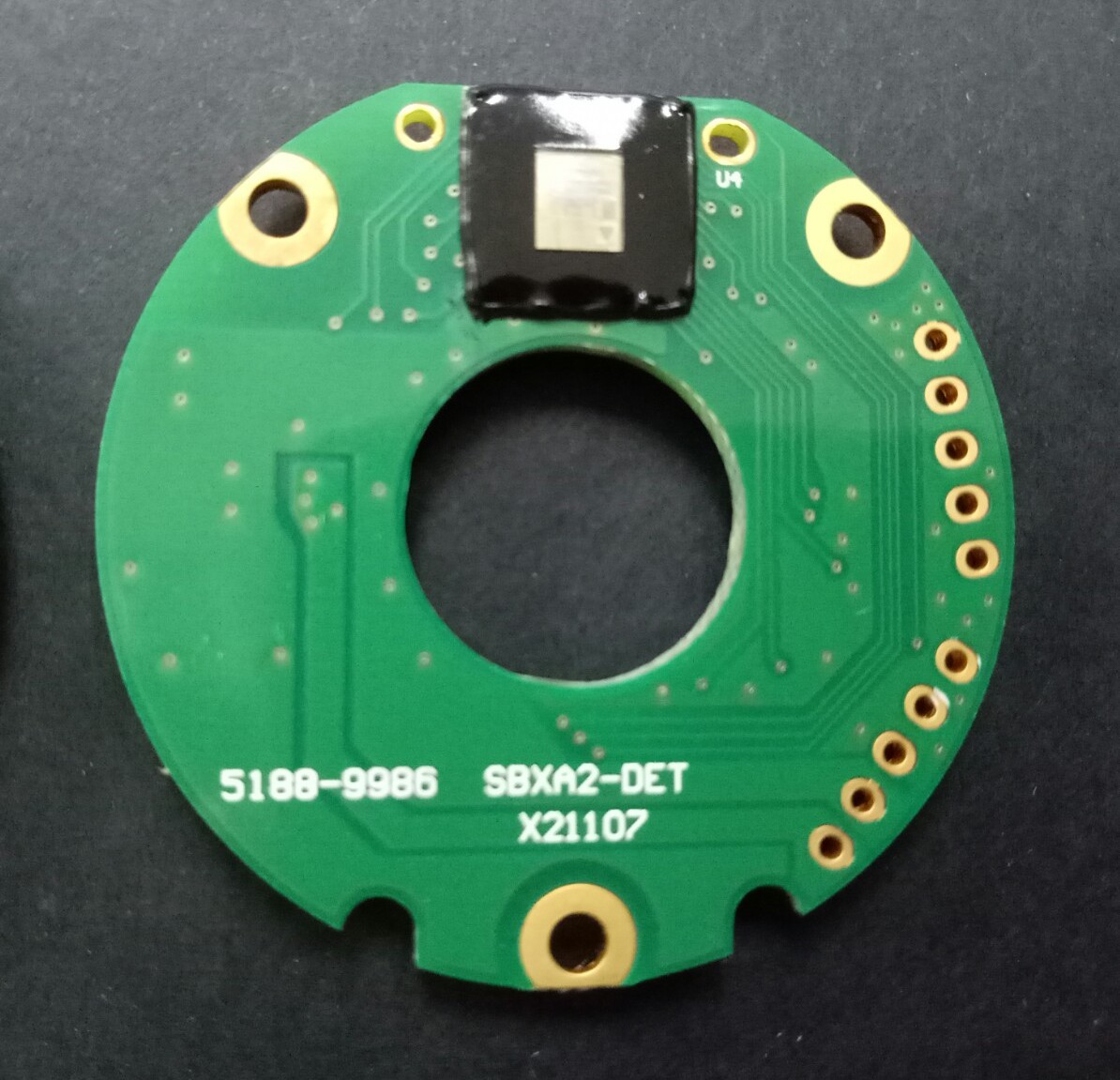

Silver Epoxy / Die Attach Silver Epoxy / Die AttachThe silver die attach has been designed for auto dispensing, stamping and screen printing with excellent adhesion on various substrates such as copper and gold. Besides the electrical conductivity, it has excellent thermal conductivity which makes it suitable for bonding components that generate heat. Application: PCBA (Printed Circuit Board Assembly), sealing and bonding of electronic components and devices. |

|||||

|

Product Code

|

Special Features

|

Appearance

|

Cure (˚C/ Time)

|

Viscosity (cP)

|

Shelf Life (month)

|

|

Silver paste | 2hrs @ 120°C, 1hr @ 150°C or 30mins @ 170°C |

25,000 |

12 |

|

|

Silver paste | 2hrs @ 120°C or 1hr @ 150°C |

65,000 | 9 | |

|

Silver paste | 1hr @ 90°C | 3,200 | 3 hours | |

|

Translucent liquid | 2hrs @ 120°C or 1hr @ 150°C |

7,500 | 6 | |

|

Clear liquid | 13mins (Gel time) & 2hrs (Cure Time) @ 120°C or 2mins (Gel time) & 1hr (Cure Time) @ 150°C. |

1,000 | 6 | |

|

Translucent liquid | 2hrs @ 120°C or 1hr @ 150°C |

7,500 | 6 | |

|

Translucent liquid | 2hrs @ 120°C or 1hr @150°C |

5,500 |

6 |

|

|

Black | 1hr @ 120°C | 6,500 |

6

|

|

|

White | 2hrs @ 120°C or 1hr @ 150°C |

5,800 - 7,800 | 6 | |

|

Silver paste | 2hrs @ 150°C | 7,000 | 6 | |

|

Silver paste | 2hrs @ 150°C | 12,713 | 6 | |

|

Black | 2hrs @ 80°C or 24hrs @ 25°C | 15,300 | 12 | |

|

Silver paste | 10mins @ 110°C or 30mins @ 80°C | 6,750 | 12 | |

|

Silver paste | 10mins @ 110°C or 30mins @ 80°C | 7,025 | 12 | |

|

Brown | 10mins @ 110°C or 10mins @ 80°C | 148,000 | 12 | |

Epoxy Sealant Epoxy SealantThe epoxy sealant is ideal for bonding and sealing various types of electronic devices such as relays, transformers and fiber optic components. It can be used to bond different types of substrates such as metal, plastic, glass and composite materials. Application: PCBA (Printed Circuit Board Assembly), sealing and bonding of electronic components and devices |

||||||

|

Product Code

|

Special Features

|

Appearance

|

Cure (˚C/ Time)

|

Viscosity (cP)

|

Shelf Life

(month) |

Tg (˚C)

|

|

Dark blue liquid | 24hrs @ 25°C or 30mins @ 70°C |

21,040 | 6 | 70 | |

|

Black paste | 24hrs @ 25°C or 3hrs @ 80°C |

3,500 | 3 | 60 | |

|

Clear +

yellowish liquid

|

15mins (Gel time) & 2hrs (Cure Time) @ 80°C or 6mins (Gel time) & 1hr (Cure Time) @ 120°C |

1,040 | 12 | 65 | |

|

Clear +

yellowish liquid

|

24hrs @ 25°C or 2hrs @ 80°C |

32,700 | 12 | 90 | |

|

White paste | 12mins (Gel time) & 2hrs (Cure Time) @ 100°C or 2mins (Gel time) & 30mins (Cure Time) @ 150°C |

42,000 | 6 | 121 | |

|

White paste | 12mins (Gel time) & 2hrs (Cure Time) @ 100°C or 2mins (Gel time) & 30mins (Cure Time) @ 150°C |

24,000 | 12 | 122 | |

|

Green | 24hrs @ 25°C | 7,500 | 12 | NA | |

|

Slightly yellowish | 45mins @ 75°C | 5,600 | 12 | 46 | |

|

White paste | Precure 60mins @ 100°C, followed by post cure 20mins @ 150°C | 37,530 | 6 | 122 | |

|

Off white paste | 2hrs @ 100°C, or 30mins @ 150°C | 35,000 | 12 | 156 | |

|

Off white paste | 2hrs @ 100°C, 2hrs @ 120°C or 30mins @ 150°C | 45,000 |

12 |

150 | |

|

White paste |

2hrs @ 100°C or 30mins @ 150°C |

24,000 | 12 | 122 | |

|

Black | Pre-cure 60mins | 47,000 | 6 | 115 | |

|

Blue | 30mins @ 150°C | 15,700 | 6 | NA | |

|

Sligh translucent yellowish | 24hrs @ 25°C or 1hr @ 80°C | 5,082 | 12 | NA | |

|

Clear |

24hrs @ RT | 1,400 | 12 | NA | |

|

Beige liquid | 24hrs @ RT | 24,400 | 12 | NA | |

|

Beige liquid | 24hrs @ RT | 200,000 | 12 | NA | |

|

Sligh translucent yellowish | 24hrs @ 25°C or 1hrs @ 80°C | 5,082 | 12 | NA | |

|

Slightly yellowish | 45mins @ 75°C | 5,600 | 12 | 46 | |

|

White paste | Precure 60mins @ 100°C, followed by post cure 20mins @ 150°C | 37,530 | 6 | 122 | |

|

Off white paste | 2hrs @ 100°C or 30mins @ 150°C | 35,000 | 12 | 156 | |

|

Off white paste | 2hrs @ 100hrs, 2hrs @ 120°C or 30mins @ 150°C | 45,000 | 12 | 150 | |

|

White paste | 2hrs @ 100°C or 30mins @ 150°C | 24,000 | 12 | 122 | |

|

Black | Pre-cure 60mins | 47,000 | 6 | 115 | |

|

Blue | 30mins @ 150°C | 15,700 | 6 | NA | |

|

Slight translucent yellowish | 24hrs @ 25°C or 1hr @ 80°C | 5,082 | 12 | NA | |

|

Clear | 24hrs @ RT | 1,400 | 12 | NA | |

|

Beige white | 24hrs @ RT | 24,400 | 12 | NA | |

|

Beige white | 24hrs @ RT | 200,000 | 12 | NA | |

|

Slight translucent yellowish | 24hrs @ 25°C or 1hr @ 80°C | 5,082 | 12 | NA | |

|

The potting epoxy and silicone are designed with excellent thermal and mechanical properties that provide maximum protection on the electronic components and devices under critical operation conditions. The viscosity has been optimized with good flow properties for filling up gaps between components. Application: PCBA (Printed Circuit Board Assembly), sealing and bonding of electronic components and devices. |

||||||

|

Product Code

|

Special Features

|

Appearance

|

Cure (˚C/ Time)

|

Viscosity (cP)

|

Shelf Life

(month) |

Tg (˚C)

|

|

Black +

clear liquid

|

6hrs (Gel time) & 24hrs (Cure Time) @ 25°C or 30mins (Gel time) & 2hrs (Cure Time) @ 80°C |

3,863 | 12 | 63 | |

|

Clear liquid | 4hrs (Gel time) & 24hrs (Cure Time) @ 25°C or 30mins (Gel time) & 2hrs (Cure Time) @ 80°C or 15mins (Gel time) & 1hr (Cure Time) @ 100°C |

17,800 | 12 | 71 | |

|

White liquid | 24hrs @ 25°C or 3hrs @ 80°C |

1,720 | 12 | NA | |

|

Clear liquid | 24hrs @ 25°C or 3hrs @ 80°C |

860 | 12 | 95 | |

|

Black + yellowish clear liquid | 24hrs @ 25°C or 3hrs @ 80°C |

32,000 | 12 | NA | |

|

|

|

Black liquid | 24hrs @ 25°C |

7.500

|

12

|

NA

|

|

Blue liquid |

Precure 60mins @ 120°C-125°C Post cure: 120mins @ 125°C-135°C |

3,200 | 12 | 24 | |

|

Black | 24hrs @ 25°C or 3hrs @ 80°C | 1,700 | 12 | NA | |

|

Black | 24hrs @ 25°C or 4hrs @ 50°C | 1,700 | 12 | NA | |

|

Transcucent liquid | 24hrs @ 25°C, 4hrs @ 50°C or 3hrs @ 80°C | 970 | 6 | -28°C | |

|

Black | 1.5hrs @ 135°C | 970 | 6 | -28°C | |

|

White | 48hrs @ 25°C or 2hrs @ 80°C | 10,464 | 12 | 45 | |

|

Black liqud | 24hrs @ 25°C or 1hr @ 80°C | 286,564 | 12 | 54 | |

|

Clear Transparent | 24hrs @ 25°C or 30mins @ 120°C | 4,600 | 12 | NA | |

|

Ligth Blue | 24hrs @ 25°C or 2hrs @ 80°C | 15,450 | 12 | NA | |

|

Translucent | 24hrs @ 25°C or 2hrs @ 80°C | 4,200 | 12 | NA | |

|

Light blue | 24hrs @ 25°C or 2hrs @ 80°C | 4,200 | 12 | NA | |

|

Blue Liqud | Pre cure, 2hrs @ 135°C or 8hrs @ 150-160°C | 360-8115 | 18 | 130 | |

|

The UV epoxy is suitable to bond fiber optic components, electronic components, LCD panels and other type of substrates such as plastic, Ultem and metals. The UV curable silicone is specially designed for COB process in the manufacturing of LED. It is more economical compare to the conventional molding process. Besides the high UPH, it gives all the excellent properties that required in high power LED. Application: PCBA (Printed Circuit Board Assembly), sealing and bonding of electronic components and devices.

|

|||||

|

Product Code

|

Special Features

|

Appearance

|

Cure

|

Viscosity (cP)

|

Shelf Life

(month) |

|

Yellowish transparent liquid | 320 - 400 nm, 420mW/cm2 for 10s | 245 | 6 | |

|

Light grey liquid | 20s @ UV 60mW/cm2 or 10mins @ 150°C | 3,500 | 6 | |

|

Clear liquid | 3s @ UV 1000mW/cm2 | 740 | 12 | |

|

Translucent liquid | 5s @ 400mW/cm2 UV Intensity | 17,500 | 6 | |

|

White translucent paste | 3s @ UV 1000mW/cm2 or 5 seconds at UV 500mW/cm2 or 15s @ UV 200mW/cm2 + 30mins @ 120°C |

12,000 | 6 | |

|

Translucent white |

Pre-cure: 2W/cm2, 15s (365nm) Post cure: 1-1.5hrs @100-130°C |

13,760 | 6 | |

|

Translucent white |

Precure: 365nm: 15sec, 2000mW/cm2 Postcure: 1hr @100°C or above. |

22,800*or 51,590** |

6 | |

|

Translucent yellowish |

(365nm):2000mW/cm2, 3-15s (380-500nm): 500mW/cm2 or above, 10s (320-380nm): 300mW/cm2, 3s (Sunlight): 30s |

7,600 | 12 | |

| ** Viscosity CP25-1, 10s-1 at 25C |

Acrylic Conformal Coat Acrylic Conformal CoatThe conformal coat provides excellent moisture and environmental protection. It is a one-component, solvent-based, air-dried coating system. It has a fluorescent agent for easy inspection under UV light. It is recommended for coating and protection of electronic parts, most plastics, ceramics and metals. Application: PCBA (Printed Circuit Board Assembly), sealing, coating and bonding of electronic components and devices. |

||||||

|

Product Code

|

Special Features

|

Appearance

|

Cure

|

Viscosity (cP)

|

Shelf Life

(month) |

Fluorescent

Agent |

|

Clear liquid | 16hrs @ 25°C or 30mins @ 80°C |

320 | 12 | Yes | |

|

Clear liquid | 16hrs @ 25°C or 30mins @ 80°C |

320 | 12 | No | |

|

Blue Liquid (Silanes) | 10-30mins dry RT | <30 | 6 | Blue color | |

|

Clear liquid | 16hrs @ 25C or 30mins @ 80C | 65 | 12 | Yes | |

|

Translucent liquid | 16hrs @ 25°C or 30mins @ 80°C | 385 | 12 | Yes | |

|

Translucent liquid | 5mins @ 130°C, 60mins @ 150°C (less surface tackiness) | 2,980 | 6 | No | |

Underfill Epoxy

Underfill Epoxy